Visual Computing as Key Enabling Technology for Industry 4.0

06.07.2015

Nowadays in the main worldwide economies there is a clear global trend focused on strengthening the industrial production capacity as a result of the last advances in ICTs. Some of these advances give new chances to increase the productivity and efficiency in advanced manufacturing. This trend shows that the relative weight of the Information and Communication Technologies in the industrial world will be greater than ever.

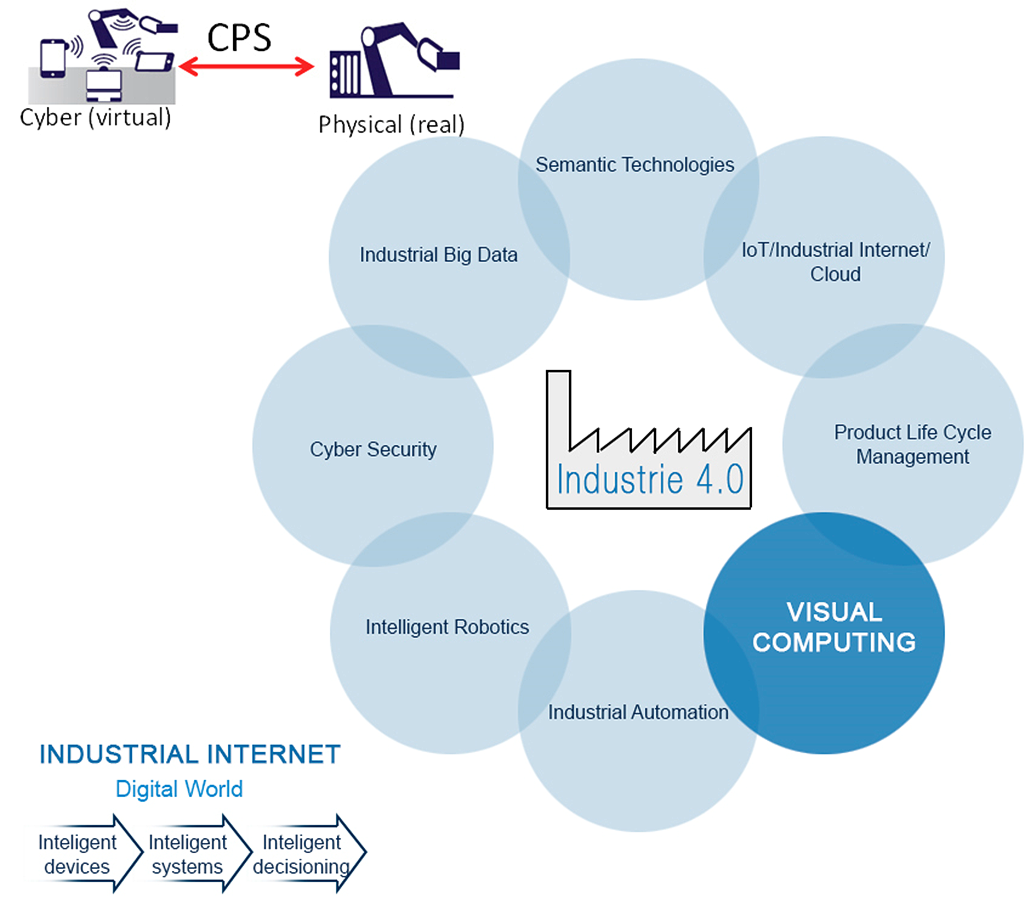

One of the main approaches in this global trend is “Industry 4.0” [1], fostered by Germany, which is the international reference in terms of vision, technology opportunities and scientific challenges. There are several essential aspects addressed by the paradigm Industry 4.0, highlighting the following ones: (i) massive customization of products enabled by ICTs, where the production shall be adapted to short batches or even single batches, (ii) the automatic and flexible adaptation to the production chains due to the changing specifications, (iii) parts and products traceability and self-awareness and its communication with machines and with other products, (iv) the improvement of the man-machine interaction mechanisms, including the coexistence with robots or with totally new interaction and work forms in the factory, (v) the production optimisation due to the communication capacities enabled for the IoT in Smart Factory and (vi) new services and business models contributing to the generation of new forms of interaction in the value chain.

In a cross-cutting manner to these all aspects, underlies the need of shortening the existing distances between the physical or productive world and the digital world. This need is translated into cyber-physical-systems or CPS [2]. These systems allow a transparent interaction between both of the worlds, enabling the emergence of the Internet of Things and Services paradigm. These systems, applied to productive processes, will allow to develop smarter machines or productive plants able to exchange information smartly and with autonomy, turning the industry into a Smart Factory.

Both the European paradigm Industry 4.0 and the American vision of Industrial Internet, together with similar approaches, are linked to a set of key technologies for the achievement of this paradigm. Certainly the Internet of Things is the main key technology. However, it is also true that there are additional technologies really necessary to obtain complete solutions, such as the cyber-security, the semantic technologies or the Visual Computing technologies.

The term Visual Computing is related to a set of technologies oriented to the acquisition, management, analysis and synthesis of the visual data and information. There are several subjects within this concept, such as the computer vision or CAD, both essential in the current manufacturing processes. These technologies will assume an increasing role as the paradigm Industry 4.0 consolidates in the industries. For example, with the aim of consolidating the concept cyber-physical systems for the industry, the procedures such as the virtual rendering of products and processes, before and during the operation, will be key processes to achieve the essential objectives in product configuration and the flexibility in production.

Modelling and simulation of processes covering the product’s complete lifecycle, from the design until its removal, it is very important, especially with the emergence of the Equivalence concept, Cyber Physics or Cyber-Physical Equivalence (CPE) [3]. This term, linked to the Cyber-Physical System (CPS) refers to the fact that physical and virtual dimensions and entities coexist in a synchronised manner over time.

This equivalence, provided in terms of digital twins, offers very interesting features since both of them may overlap and exchange data between them in a transparent manner. Advanced Computer Graphics Visualisation and Interaction techniques, apart from other technologies, for its execution in a real scenario, are essential in order to achieve this convergence. This equivalence could be given not only for products but also for processes, machines or productive plants. The virtual simulation mechanisms of processes shall be ready for facing up new trends and needs of the market that need to deploy for example, control and production strategies based on auto-organisation [4].

Within the paradigm Industry 4.0 the machines and/or the processes will not be the only principal players, but also the persons will play an essential role in this new scenario. In addition to advancing in support technologies to develop and foster the cyber-physics equivalence, a new generation of Man-Machine Interaction mechanisms applied to industry are required for the optimisation of the manufacturing work configuration, including not only the machine and production lines working but also the training of the workers. The traditional machine operating mechanisms could be oriented in the future towards new interaction forms where the advanced graphics interface development, with special focus on the use of mobile devices, for the interaction with different CPS entities, heterogeneous in nature, will have an key role.

The operators’ empowerment is becoming increasingly important through the use of tools which enable continues training processes, together with access and data processing tools such as the augmented reality or the visual analytics, able to provide contextualised information and hence help on the decision making process.

The Visual Computing technologies may become key technologies for the execution of the Industry 4.0 and Industrial Internet paradigms. These new trends are offering new opportunities to increase and improve the productivity and are encouraging the emergence of new business possibilities and opportunities which allow to ensure the future of the manufacturing in the most advanced economies.

References

[1] Kagermann, H., Wahlster, W., Helbig, J. "Umsetzungsempfehlungen für das Zukunftsprojekt Industrie 4.0." (vorabversion) 2012. http://tinyurl.com/pq5ltm6

[2] Lee, Edward A. "Cyber physical systems: Design challenges." Object Oriented Real-Time Distributed Computing (ISORC), 2008 11th IEEE International Symposium on. IEEE, 2008.

[3] Lukas, U., Stork, A. "Visual Computing für die nächste industrielle Revolution Economic Engineering: Intelligente Methoden.", Prozesse und Technologien,4, pp. 36-38, 2013.

[4] Priego, R. Orive, D. Marcos, M. “Maintaining the availability of the Control System in Industrial Automation.” Agenten im Umfeld von Industrie 4.0. pp- 15-19. Sierke Verlag 2014.