Vicomtech develops a reconstruction system for surface inspection of broaches for Ekin

Vicomtech has developed a system that automates the quality inspection process of the broaches manufactured by EKIN, improving and facilitating the inspection of the broach to the operator, and reducing the time dedicated to the inspection of each of them.

18.12.2019

A broaching machine is a machine used in industry to make external and internal surfaces difficult to access, for example, grooves. For this purpose, it uses a broach, a cutting tool with multiple edges. Broaching consists of a continuous cutting process, with rectilinear cutting movements, applied to the brocach or the piece. The broaches are designed for forward and bachward movements in machining processes and are formed by a series of teeth or molars, twins together, throughout a revolution (360º). The different components differ in the geometry of the molars and in their spatial distribution along the length of the broach.

Ekin carried out the inspection of their manufactured broaches manually by an operator through a magnifying glass and a moving car tool. Manually it took approximately 2 hours to inspect a component. Due to the high precision in the broaches required by Ekin's clients, both in the aeronautical and automotive sectors, the validation of the quality of the broach is a fundamental step in their production process. Each broach is designed exclusively to make a certain geometric shape and therefore differs greatly from others.

The challenge of this project has been to address the following objectives

- Automate the inspection process

- Acquisition of the surface of the broach by artificial vision

- Analyze the quality of the surface of the broach in the case of Ekin.

. The development consists of a superficial inspection system by means of artificial vision with a specialized analysis software developed for the use case of Ekin. In this way, the process is digitalized: i) improving and facilitating the inspection of the surfaces of the broaches to the operator, as well as ii) reducing the time dedicated to the inspection of each broach.

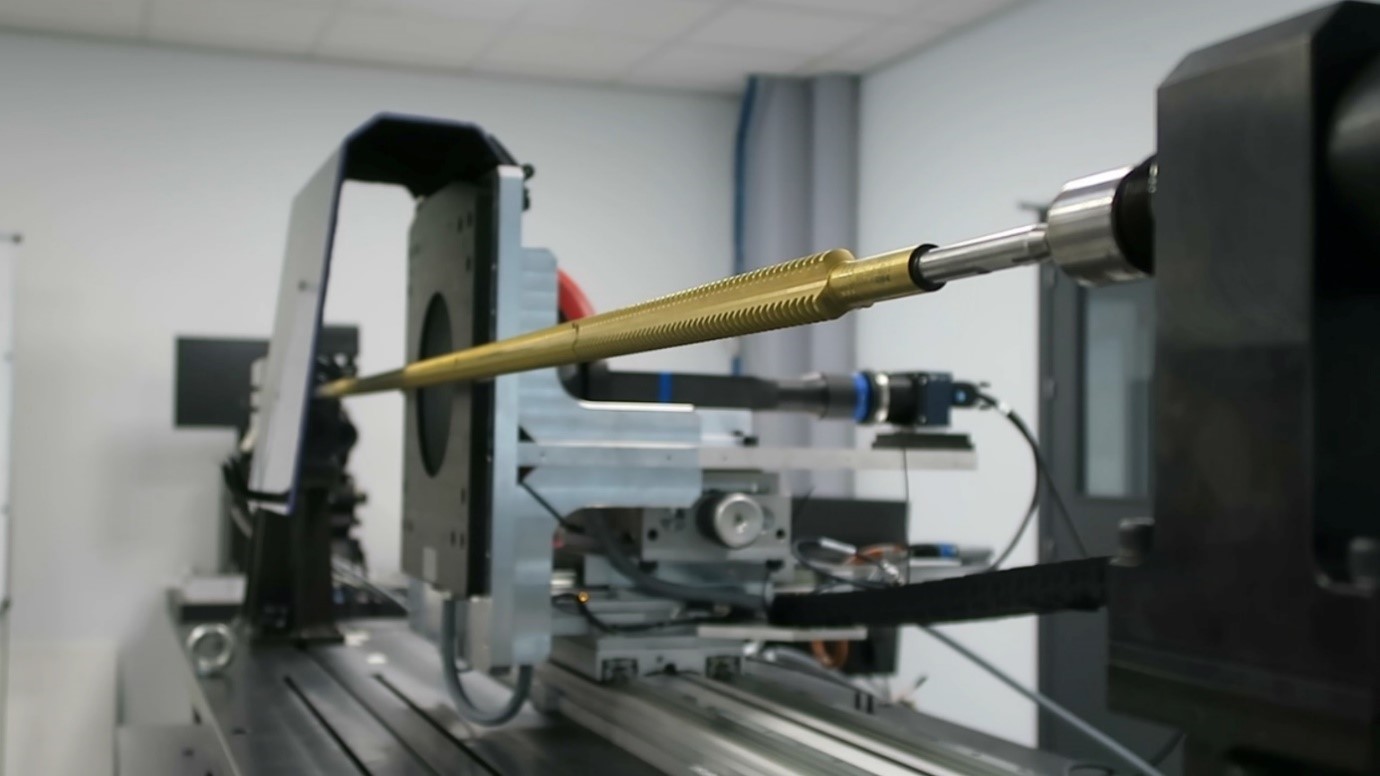

The system proposed and developed by Vicomtech, provides an automatism very similar to a 3-axis CNC lathe, so that the broach is mounted between a broach tie plate / tooling and a counterpoint. The plate rotates the broach at a certain speed and the tool carriages are used to position the artificial vision system on the X, Y, Z axis.

The image capture of the component is performed in a linear capture system that can be controlled by the automation, making use of photometric stereo reconstruction.

Finally, the analysis software developed from software libraries owned by Vicomtech, identifies for each section of 3 or 4 teeth the surface defects that the broaches contain.

The new developed system, offer Ekin a competitive advantage over the competition. In addition, by having an advanced inspection system, allows them to consolidate its position both nationally and internationally, bringing the following improvements to their manufacturing process.

- Cost reduction: The inspection will be carried out in a shorter time, and will also help to ensure the manufactured broaches do not contain defects. Therefore, the production costs of each broach will be reduced.

- Improvement in the quality of work: The manual inspection supposes a prolonged visual overexertion for the operator that in the long run can cause health problems such as eyestrain, for example. By digitizing and automating the process, these types of problems will be reduced by making better use of human resources.

- Improvement of quality process management: With the digitalization of the process, information technologies will be exploited at the same time to generate reports, historical data, improve communication with stakeholders, etc.

- Increased knowledge of the process: Offering Ekin's quality and ensuring defectology through the use of new technologies such as artificial vision will be an added bonus to Ekin's well-known technical solutions

The project has had the participation of Ekide Group and has been financed by the SPRI Basque Industry 4.0 Program.