Intelligent sensorised cutting tools through functional coatings

INTOOL2

Duration:

01.03.2020 - 31.12.2021

Aim of the project

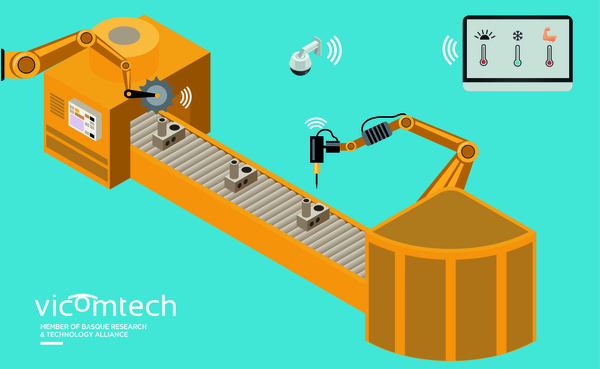

Develop a sensor with functional coatings, which allows more accurate and robust information to be obtained on the real situation of the machining process: forces, temperatures, degree of tool wear, etc.

Role of Vicomtech

Vicomtech has been in charge of developing the tools based on artificial intelligence. This can transform the complex signals coming from the novel sensors developed in the project into processed and useful information to help improve the company's business intelligence.

Technologies used

- Machine Learning

- Data Analytics

Field of application

This project has been done with the aim of applying it to the manufacturing sector.

Project partners

- Mondragon University (coordinator)

- BCMaterials

- Ikergune

- Sidenor I+D

Project financing

- SPRI

Looking for support for your next project? Contact us, we are looking forward to helping you.