Inline measurement technology inspection development for high cadence hot stamping processes for automotive components

MEDLINE

Duration:

01.03.2017 - 31.12.2017

Inline measurement technology inspection development for high cadence hot stamping processes for automotive components

The manufacturing process of a hot stamping line, like many other processes on the manufacturing world, can produce defective parts. The identification of this parts as soon as possible allow, among other things, stop defective manufacturing batches produced due to problems in a machine, with all the time and resource savings that come with it.

Being able to measure the parts as soon as they are out of the stamping process would be ideal, but this type of processes face two big challenges. On one side, the parts are being manufactured at a high pace; on top of that, they exit with a very high temperature, making it difficult to manipulate it.

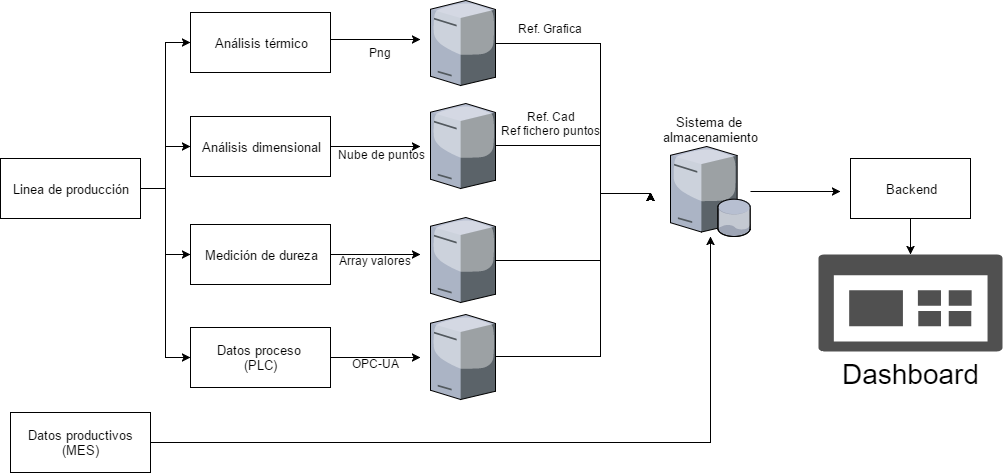

With the objective of making different measures to the part (temperature analysis, dimensional analysis or hardness analysis among others) and being able to manage all the information coming out of the different sensor modules in real time was the MEDLINE project born.

Looking for support for your next project? Contact us, we are looking forward to helping you.