SSOPI (Smart Scheduling Optimization for Production Industries)

SSOPI

Duration:

14.10.2024 - 31.12.2025

SSOPI Project Context

In the current context of digital transformation in the industrial sector, many small and medium-sized enterprises face the challenge of optimizing their production planning and scheduling processes. The increasing complexity of environments—due to customized products, limited resources, and volatile demand—makes it essential to have advanced solutions that improve operational efficiency and support flexible decision-making.

Project Objective

The SSOPI project (Smart Scheduling Optimization for Production Industries) was launched with the aim of addressing this challenge through the development of digital tools that enhance medium-term planning and detailed sequencing of manufacturing orders. The initiative is funded by the PADIH program, under the Recovery, Transformation, and Resilience Plan, supported by the Next Generation EU funds.

Vicomtech's Role

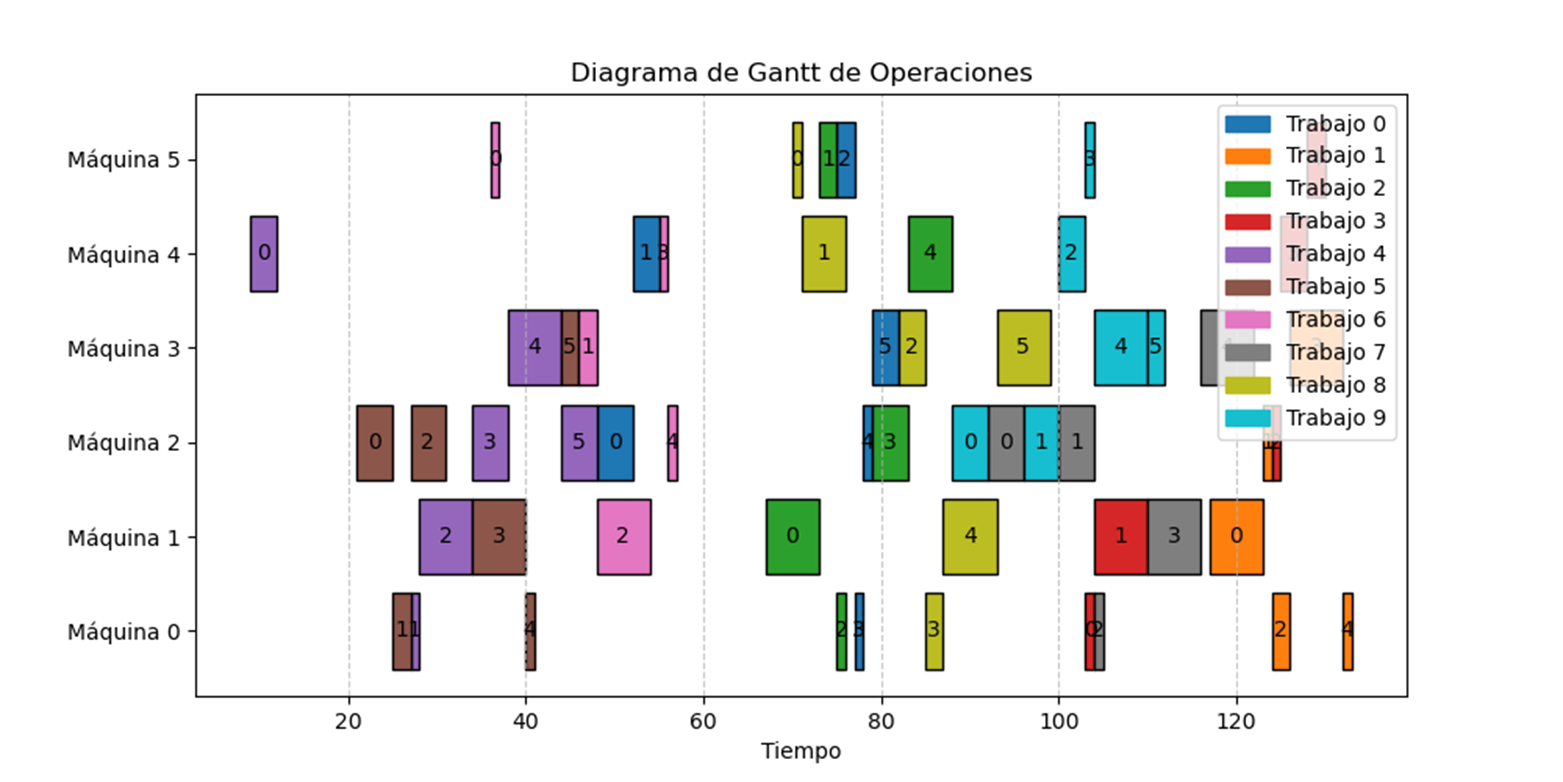

Vicomtech brings its expertise in optimizing the Flexible Job Shop Scheduling Problem (FJSSP), a widely recognized challenge in operations research.

We have proposed the design and implementation of advanced mathematical models for industrial planning, using techniques such as Mixed-Integer Linear Programming (MILP) for aggregate planning scenarios and Constraint Programming (CP) for complex sequencing problems on the shop floor.

These models will be applied to a real use case at the company TMC Cancela to validate their usefulness and scalability in real industrial environments.

The design will be modular and generalizable, allowing these solutions to be incorporated into various industrial operations management scenarios (MES/ERP).

Proposed Solution

The proposed system is structured into two interconnected modules:

-

Demand Planning Module: Estimates reliable medium-term delivery dates based on current and forecasted workload, helping improve order promise reliability.

-

Operations Scheduling Module: Dynamically assigns tasks to production resources considering operational constraints, machine and operator availability, and priorities, optimizing daily shop floor execution.

These modules are integrated with Zerintia's industrial solution through a flexible architecture, providing advanced automated decision-making capabilities in real industrial environments.

Project Partners

The project is being developed in collaboration with Zerintia Technologies, a company specialized in the digitalization of industrial operations through technologies such as IoT, augmented reality, and MES systems. Zerintia contributes its 4Manufacturing platform to the project, already deployed at clients like TMC Cancela, where the optimization capabilities developed by Vicomtech will be integrated.

Although TMC Cancela is not directly involved as a partner, its use case is employed as a real validation and technology transfer environment, demonstrating the applicability of the system to complex industrial scenarios and its extensibility to other Zerintia clients.

Looking for support for your next project? Contact us, we are looking forward to helping you.